Articles & photos

| Back |

13-9-2018 1125CR Big Service

22-3-2019 - What did we do today 13-9-2018: Buell 1125CR big check up , valve lash and spark plugs and charging fix

on with 1125 pod covers off

ignition gasket on

little bead of sealer on the rubber gater

hold the neutral switch wire out the way

and start mounting the bolts .. place the ones with crush ring back on the designated place —

remove the old silicone used from the bolts

ignition timing sensor in and leave the stator cable for now as we going to drop the engine

side pod loose

and leave it hanging

exhaust loose

and remove

and remove

right side pod loose

just checking.. never been done on this bike i think

.jpg)

some crud , as everything runs in the same oil , normal to find a little

pulling out the strainer and cleaning it

pulling out the strainer and cleaning it

strainer back inn and cove back on

on with the service.. rear wheel check.. pich bolt loose size 10 mm —

rear caliper loose using the big holes in the disk ( made for this )

belt is ok

rear bearings nog... feeling crunshy

new bearings in

.jpg)

and setting axle to tq counter clock wise

bike turned around and airbox cover of

always take care pulling of the lower airbox..as these bikes are dirt suckers and allot is left lying loose in the airbox

so intake some protection against the dirt , and pull the airbox of

to have better acces to the rear valve cover remove the solinoid with bracket and al

smart to take the power off

and moving in from the front. caliper and wheel out

front bearings are ok

.jpg)

caliper on holding position

fork legs out

center engine bolt loose and out

disconnect the rear O2 sensor

and take the front brace bolts out

intake duct out

and loosen the cables left brace , cut the zipties and pull the tabs on the horn

.jpg)

loosen the clutch master to give the line more lenght , put some protection over it

ignition cover remove the plug

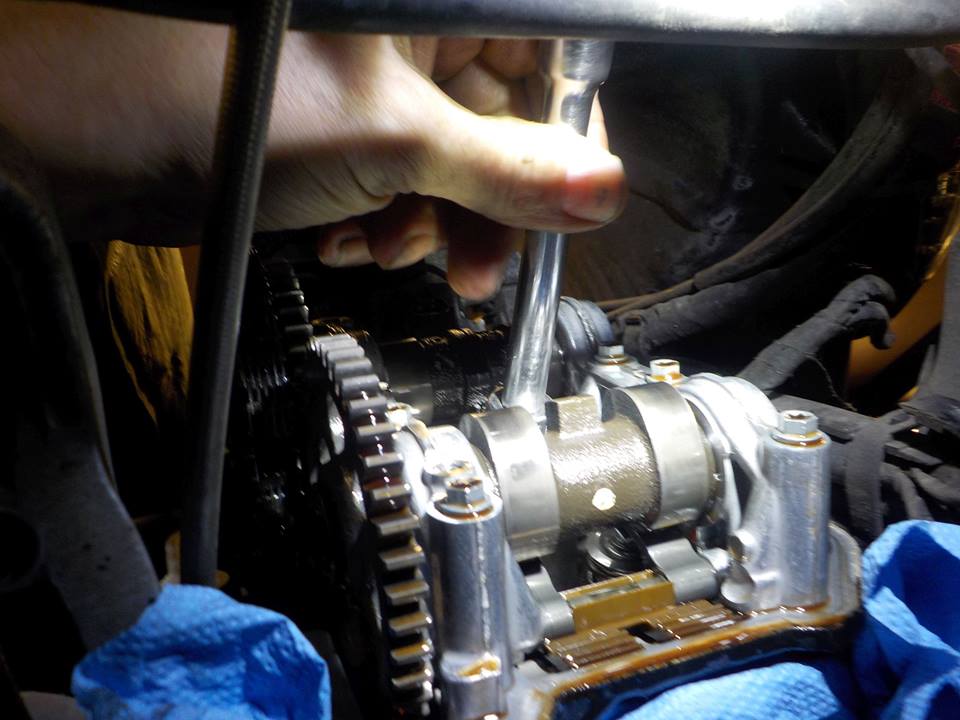

to get to the crank drive ( 16 mm hex )

a little light so i can see what i'm doing

a little light so i can see what i'm doing

giving the rear O2 sensor wire more room

if more needed , cut the loom open.. normaly it will do

stick coil out

.jpg)

and cover of .. use a napkin under the head.. for oil spill in the header

spark plug out

not bad. but still customer will notice there are new ones in

not bad. but still customer will notice there are new ones in  :-)

:-)

valve lash is still with in specs.. will need adjustment in the next big service , cams look very good —

checking the cap on these to

checking the cap on these to

plug in and stick coil in .. make sure the coil connector locks .. other wise secure it with a small ziptie , to morrow finish