Articles & photos

| Back |

25-1-2018 XB 88CI first km done, oil change

6-4-2018 - 25-1-2018 Buell XB12 88CI first km done, oil change, clutch, Buell M2 leaking intake seals, Buell XB12X service check up.

M2. not running right

.jpg)

customer did check hime self.. double check.. yep seals are leaking

fuel tank of makes the work much easie

loosen the choke cable

fuel hose off

and start loosening the alen bolts

.jpg)

moving to the other side.. cover off

and base plate needs to come of

the breather lock nut loose

short intermetzo 50 km on the dyno with break in oil .. time for oil change

it has done its work.. extra protection

i will replace the cltuch spring to now.. so it can take more power

cover removed and clutch tool on

.jpg)

mounting the stronger spring.. for the street the stock one will hold a long time.. on the dyno... forget it , half way during tuning it will start to slip

some loctite on the shifter screws

oil back on

oil back on

mnn ok sweating some from the case pressure .. cleaned it and used some silicone under the extra bolt

and mounting the airbox now.. so the intake will be as it will be on the road

.jpg)

ready for dyno session 2

on with the M2 the breathers are making things messy.. will clean and try to fix

intake manifold of

the seals are hard and cracked

.jpg)

there whare blue ( thicker ) seals on.. but looks like the normal ones will do just fine

aline the manifold while your fastening the screws

carb back on

cleaned and hydraulic locite on the breather bolts

and tightening the counter nut

breather hose on.. now with a little ziptie to clamp theme harder

.jpg)

base plate back on

and cover on .. nice

fuel tank on with 1 bolt

customer needed a harder rear spring ( duo riding ) so adjusting a little with my small crescent wrench

the canister needs to move back to stiffen the spring . put it 5 mm harder

long time not seen this bike... very well known bike.. one off our first test bikes, for exhaust fitting ect.

very rare oem camo kit was mounted.. very nice

she has not done much km .. and runs still very nice.. altough i hate the front exhaust in the work shop , to suck the fumes, sucks

.jpg)

some things you notice right away.. very heavy preload on the springs.. i think to much

dry paper race filter

why do people think this is a k&N and oil it ?

.jpg)

breather hoses where positioned wrong, the need to cross to fit nice

old times... :-)

:-)

so to drain the oils

;-) did i mention ulys can corner very well

;-) did i mention ulys can corner very well

the custom made clutch cover, has a crack , sutch a pitty

grrrr one screw douse not want to play nice

.jpg)

with a sharp T27 and allot off pushing it would come, but a new one needs to be mounted

oil plug , is about clean, as we would like to see

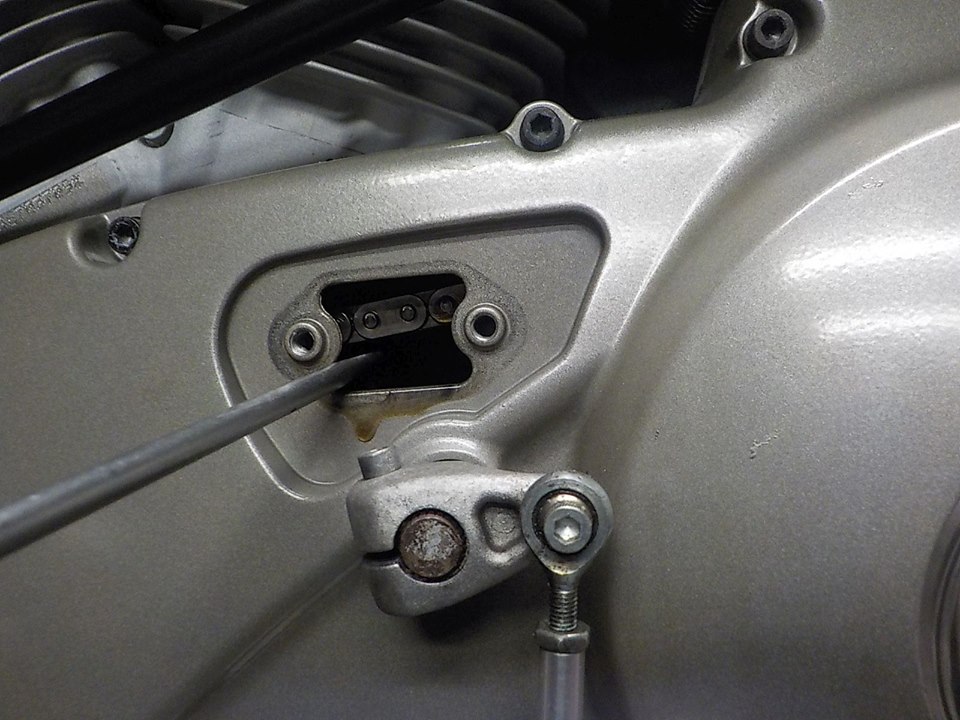

noted the VR cable hangs loos... i have seen these vibrate through on the oil pressure sensor. will fix it

mounting the cover back.. the crank is big

i mount some underlayment rings to save some pressure

adjusting the clutch cable abakc ok

.jpg)

and some ziptie to mount this better , so it wil not vibrate

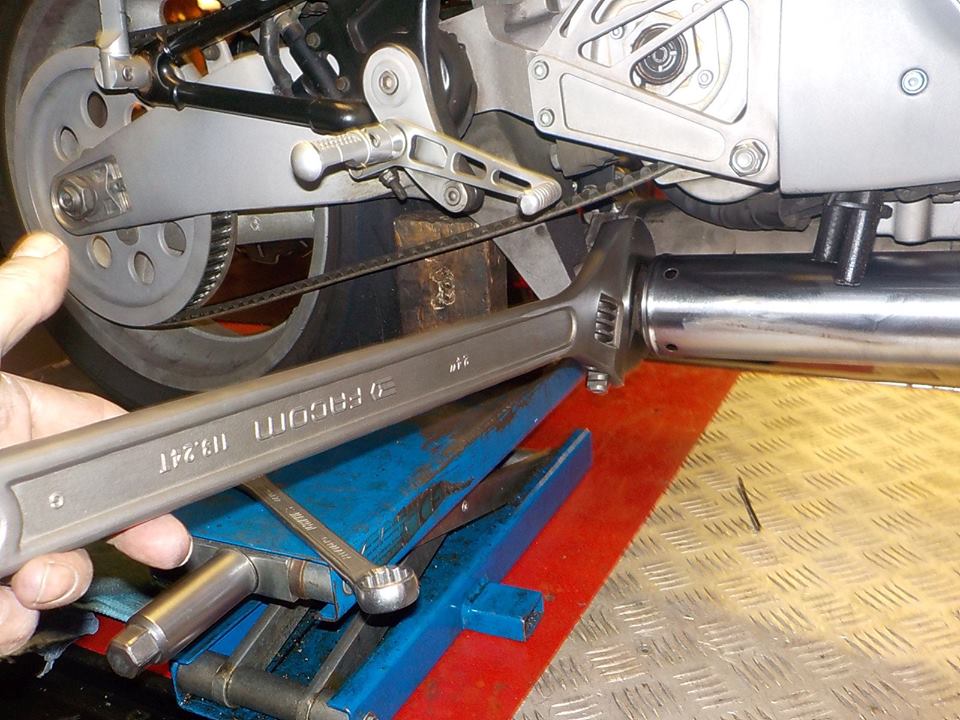

some axels are way to freaking tight , breaker bar and needed to pull on it

rear wheel bearings are ok

belt is ok but with a note keep it in check

checking the primairy chain

moving up some, this cable is toast.. note the running marks

setting the gap on the new spark plugs

.jpg)

put the spark plug cables on to the run free off everything , push theme inword

a real K&N filter on

and front side check

will do this good when ready

loosen the front screen , to support the bike

front wheel bearings feel funcky.. in al cases, if you feel anything replace these

the fork top caps are still virgen

trying to keep theme like that, some isolation tape to make the socket fit better and do not damage the soft Alu

down site Uly, front legs. there is alot off space that will never go full in the suspention.. , this one shows corrossion.. , if you colaps this wiht out noring you will fuck up the ecm

indexing teh settings

fork oil level sweet spot.. with spring just below the surface

cleaning the leg and leave a little oil on the lowers for corrosion protection

before the left leg is back on.. check the front ground points

.jpg)

the old bearings sound like a rattle

50 nm for better and longer fun

the front fender center screw for headlight adjustment

lower fender back on

and changing the brake fluid

pressing down the suspention a fewatimes

running warm to se tthe oil level